Making a vivid splash across the worlds of beauty, fashion, home interiors, graphic design, advertising and marketing, comes the announcement of the 2023 PANTONE Color of the Year: PANTONE 18-1750 Viva Magenta. Made official on December 1, 2022, this startlingly colorful message to the world, embodied in the luxurious blend of red and blue, hot and cool, retro and up-to-the minute vibes that is 2023 PANTONE Viva Magenta, positively blossoms with its many possible applications. From paint, to signage, to point-of-sale displays, to our favorite medium for marketing messages, labels, Viva Magenta is a vibrant color that you would do well to explore, to discover what it might hold in store for your product or industry.

In this blog post, we will deal with PANTONE's newest color of the year for 2023. For a discussion of the newest PANTONE Color of the Year, check out our latest blog post on the topic: Warm Up Your Labeling With PANTONE's 2024 Color of the Year.

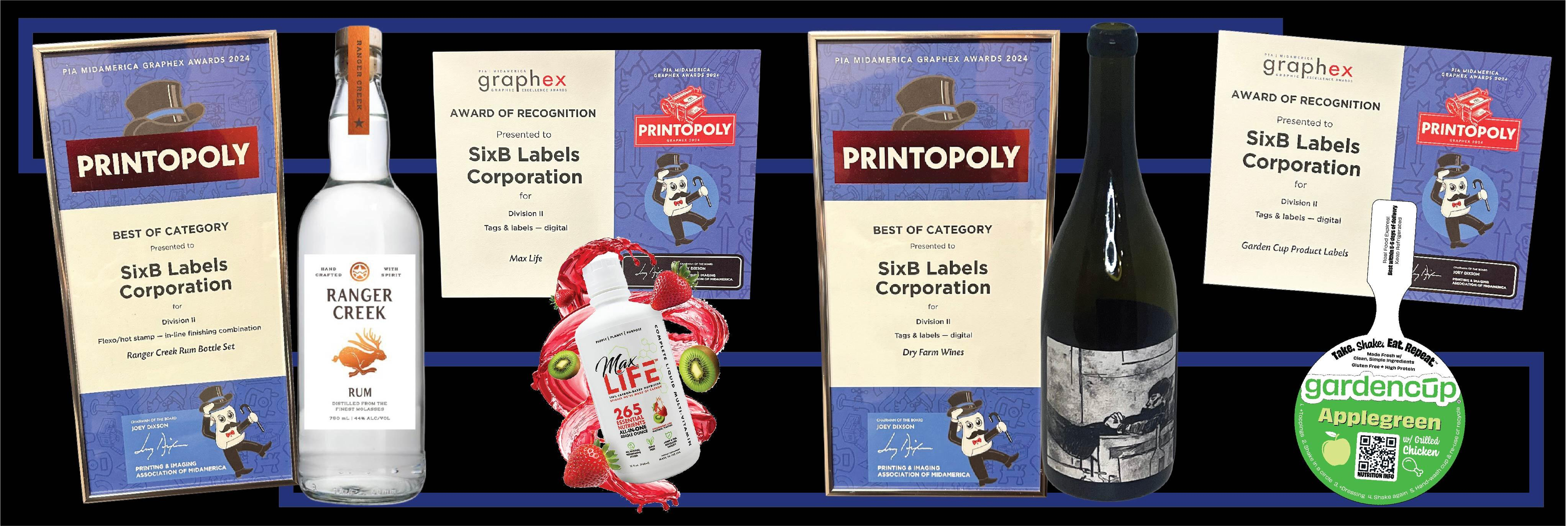

Due to their high visual impact, we love to incorporate these new PANTONE colors into our marketing, and as we have in the past, we have taken the liberty to design some logos for the occasion showcasing this spicy shade, featured here.